Electronic platform scales often experience various failure scenarios, and multiple factors can lead to these issues. Both the internal components of the weighing system and the external environment might contribute to malfunctions. Interestingly, the same fault symptom can stem from different causes. Therefore, when troubleshooting, the first step is to identify and confirm the location of the fault. Fault diagnosis typically relies on observing the fault symptoms, analyzing the system's structural components, evaluating the functions of individual parts, and considering common fault types encountered in maintenance routines. This process involves checking all potential fault-causing elements and using tools like multimeters, signal generators, and diagnostic instruments to test suspected areas systematically until the faulty component is pinpointed.

**(1) Steps for Troubleshooting**

Observe the fault phenomenon → Analyze the cause of the fault → Locate and confirm the fault → Repair the faulty part → Verify the symmetric load system and debug the system → Restore normal operation.

**(2) Basic Methods of Fault Diagnosis**

Intuitive Method: Through visual observation, check if the mechanical parts of the scale body show signs of deformation, if the limit devices touch the scale body, if the level of the scale body is uneven, and if the electrical components exhibit any broken wires, burned-out parts, or abnormal power supply conditions.

Alternative Method: Replace potentially damaged components, circuit boards, or simulated parts with functional ones to verify functionality. For instance, if the meter operates correctly, the issue likely lies with the weighing platform; conversely, if the meter malfunctions, the fault resides within the meter itself.

Measurement Method: Utilize tools such as a multimeter or oscilloscope to compare the voltage, resistance, current, and waveform readings of suspect components against standard values to uncover the root cause of the fault.

There are numerous repair techniques for electronic platform scales. In practical repair work, each specific fault requires detailed analysis. The analytical approach is paramount, as fault situations vary widely and cannot be addressed rigidly. Solving problems often demands applying multiple inspection methods. It’s crucial to remember the resistance and voltage values at key test points in the circuit. Additionally,ç•™æ„ any signs of open or short circuits in critical components. Proficiency in using common test instruments and assessing component quality is essential. Familiarity with the performance, technical specifications, and pin definitions of integrated boards further aids in improving troubleshooting skills. With these competencies, one can effectively diagnose and resolve a wide range of faults in electronic platform scales.

Long Lifespan: Superior to traditional deep-cycle Flooded/AGM batteries, our products promise extended service life.

High-Temperature Resilience: Outperforming AGM batteries in high temperatures, the EVG series guarantees consistent performance.

Low-Temperature Operation: Excelling where Flooded batteries falter, our batteries deliver reliable power in cold conditions.

Consistent Performance: Enjoy stable ampere-hour capacity and high operating voltage throughout the battery's lifespan.

Maintenance-Free Excellence: Bid farewell to spills and gassing with our nonspillable, maintenance-free design.

Aerial Lifts and Fork Lifts

Golf Carts and Wheelchairs

Floor Sweepers and Electric Vehicles

Mobility and Medical Equipments

Connect with Us:

Share your needs, and our team of battery specialists will be in touch to provide a personalized power solution for you or your company.

Unleash the Power of Innovation with OREMA EVG Series Industrial deep cycle batteries! Catering to both aftermarket and original equipment needs, our GEL traction batteries are a testament to exceptional performance and reliability. Ideal for a range of motive power applications, the OREMA EVG series motive power batteries stands out in the competitive market.

Key Features of OREMA GEL semi-traction battery:

Innovative GEL Technology: Experience the future with our cutting-edge GEL formula, ensuring longevity and efficiency.Long Lifespan: Superior to traditional deep-cycle Flooded/AGM batteries, our products promise extended service life.

High-Temperature Resilience: Outperforming AGM batteries in high temperatures, the EVG series guarantees consistent performance.

Low-Temperature Operation: Excelling where Flooded batteries falter, our batteries deliver reliable power in cold conditions.

Consistent Performance: Enjoy stable ampere-hour capacity and high operating voltage throughout the battery's lifespan.

Maintenance-Free Excellence: Bid farewell to spills and gassing with our nonspillable, maintenance-free design.

Applications of OREMA GEL deep cycle traction battery:

Marine and RVAerial Lifts and Fork Lifts

Golf Carts and Wheelchairs

Floor Sweepers and Electric Vehicles

Mobility and Medical Equipments

Solar and Wind Renewable Energy

Quality Standards:

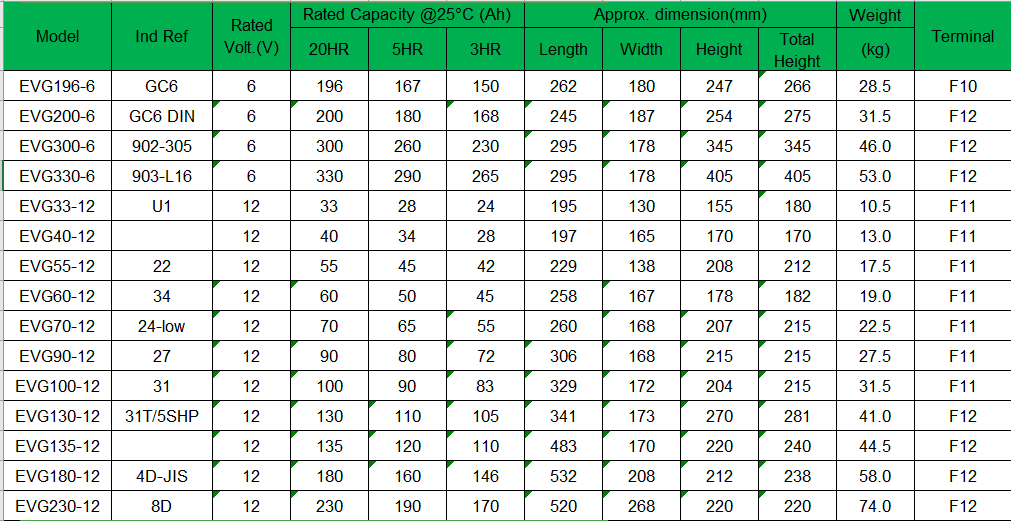

Committed to excellence, the OREMA EVG series complies with IEC, BS, JIS, and EU standards. Our UL and CE certified batteries, produced in ISO45001, ISO9001, and ISO14001 certified facilities, ensure top-notch quality and safety.OREMA EVG Series GEL Motive Power Battery specification sheet:

With a rich heritage in safety and reliability, the OREMA EVG series batteries excel in Partial State of Charge (PSOC) operation and high-temperature conditions. Let us meet your specific power requirements with our customized, reliable power solutions. Trust in our team of battery experts to power your business forward.

Connect with Us:

Share your needs, and our team of battery specialists will be in touch to provide a personalized power solution for you or your company.

GEL deep cycle traction battery,Industrial deep cycle batteries,GEL motive power battery,GEL traction batteries,GEL semi-traction battery

OREMA POWER CO., LTD. , https://www.oremapower.com